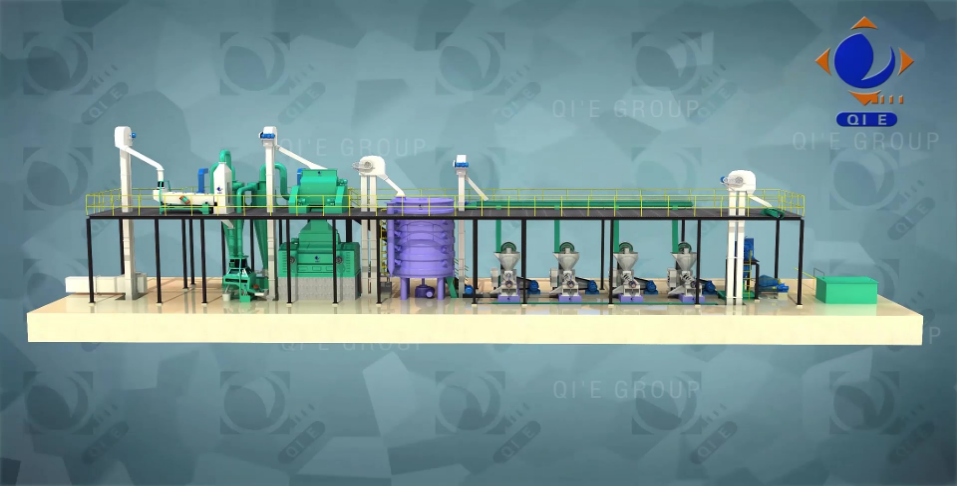

Sesame Oil Processing Plant

The complete seseme oil product line include the following steps: cleaning, cooking, oil pressing, filtering etc. We can do fragant seseame oil. Also has special intensified pretreatment technology for aroma sesame oil to make it more aroma.

Sesame Oil Extraction Plant Process:

Cleaning → Cooking → Pressing → Filtration → Sesame oil

Cleaning section

include vibrate cleaning sieve, magnetic separator, destoner to remove small, big, light impurities, stone, and metal impurity etc, to make the sesame clean. Also linked together with dust control system to keep the warehouse clean.

Cooking section

The steam cooker can improve the temperature and decrease moisture of the sesame, which make the sesame into the best condition to get oil, the cooker will break the cell wall, it can make the oil come together, the oil is easily to extract out.

Also can use roaster, to make sesame with strong smell, and get aroma oil.

Pressing section

The special screw oil expeller is used here to extract oil out of sesame, the structure of oil expeller has been designed to make the oil residue less.

Filtration section

The filter is used here to remove the cake fine, and other impurities from the sesame, the filtered oil is very clearly, can be sold directly.

Successful Cases

-

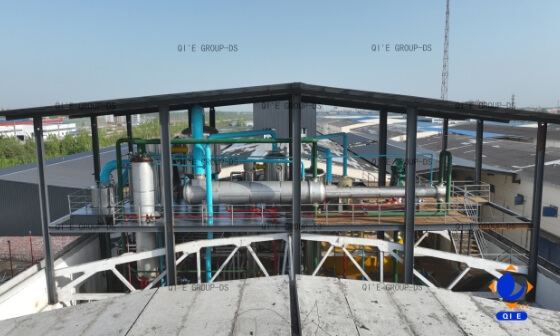

2000TPD Palm Fruit Oil Production Line In Indonesia

2000TPD Palm Fruit Oil Production Line In Indonesia -

400TPD Rice Bran Oil Solvent Extraction Plant In China

400TPD Rice Bran Oil Solvent Extraction Plant In China -

100TPD Edible Oil Refining Project In China

100TPD Edible Oil Refining Project In China -

300TPD Soybean Oil Production Line In Egypt

300TPD Soybean Oil Production Line In Egypt -

300TPD Soybean Oil Processing Line In Egypt

300TPD Soybean Oil Processing Line In Egypt -

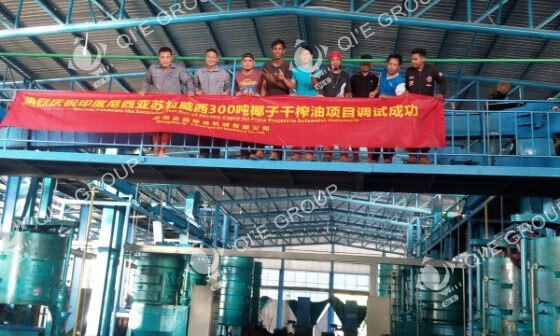

300TPD Copra Oil Production Line In Indonesia

300TPD Copra Oil Production Line In Indonesia -

200TPD Soybean Protein Isolate Project In Serbia

200TPD Soybean Protein Isolate Project In Serbia -

200TPD Soybean Oil Production Line In Russia

200TPD Soybean Oil Production Line In Russia -

200TPD Cooking Oil Production Line In Uzbekistan

200TPD Cooking Oil Production Line In Uzbekistan -

150TPD CottonSeed Oil Production Line In Uzbekistan

150TPD CottonSeed Oil Production Line In Uzbekistan -

120TPD Oil Refine Production Line In Egypt

120TPD Oil Refine Production Line In Egypt -

100TPD Palm Fruit Oil Production Line In Thailand

100TPD Palm Fruit Oil Production Line In Thailand

Language

Language