GRAIN OIL TURN-KEY PROJECT——EPC

Founded in 1982, QIE Group is a large-scaled joint-equity enterprise which is specialized in producing edible oil mechanical equipment and it is also a group enterprise integrating scientific research, manufacturing, and sales as one. It has been carrying out R&D and application of new technologies in oil machinery, protein production, and phospholipid extraction for a long time.

40 years of innovation and development, 130,000 square meters of intelligent production base, 139 patents and honors, all products have passed ISO9001:2008 international quality system certification, EU CE certification and customs union CU-TR certification, successfully serving more than 100 countries and regions around the world. Thousands of customers.

-

Project

Planning -

Technology

Design -

Equipment

Manufacture -

Installation&

Commissioning -

After-sales

Service

- Establish project, and assign professional project manager.

- Fully communicate, and fully understand customers’ needs

- Market research, and make factory suggestions.

- Analyze comprehensively , and design the suitable process plan.

COMMUNICATION >> PROJECT DESIGN

- Civil engineering, professional engineers work together

- Equipment layout, compact and reasonable placement of equipment

- Installation guaranty, dispatch a professional installation team

- Trial operation, customer acceptance of project results

ESTABLISH >> CONSTRUCTION AND INSTALLATION

- Quick response, 24/7 after-sales service.

- Spare parts supply, sufficient to be distributed nearby.

- Return visit activities, regular return visits to give guidance.

- Equipment maintenance, regular training on equipment maintenance.

SERVICE >> AFTER-SALES

WHY EPC?

Reasons for choosing EPC project general contractor

-

01

ACCURATE CONTROL

Accurately manage and control cost accounting, scientifically calculate expected profits, realize cost reduction and increase efficiency, to make sure that profit can be expected.

From the early stage equipment selection and program planning, to the mid-term equipment capacity optimization and improvement, and then to the later after-sales service, we have professional project managers to follow up the whole procedure to avoid risks and enhance the value of the project.

-

02

CUSTOM SERVICE

According to the actual requirements of clients, QIE has developed multiple sets of process plans for comparative analysis, select the reasonable plan, and realize private customization.

Our service runs through all aspects of on-site terrain and environment survey, production line process design, raw material inspection, cost requirement analysis, project investment budget, equipment installation and commissioning.

-

03

TRAINING SUPPORT

Technical personnel will be dispatched to provide systematic training, in order to better meet the needs of the project.

During the operation of technical staff, our training instructors will also continue to follow up the project operation to ensure the orderly development of the project.

-

04

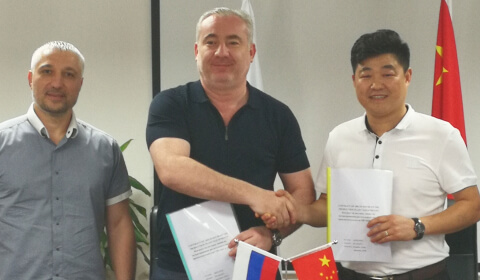

WITNESS TOGETHER

Focuses on successful cases in 100+ countries and regions around the world, and inspect every process from a single machine to the entire production line.

Thousands of clients’ successful cases has shown clear and testable operating profit ratio. And it has tested the entire service system from design and R&D team to the installation and maintenance team, to witness the realization of the investment value of the entire project.

EPC SELECTED CASES PRESENTED

-

2000TPD Palm Fruit Oil Production Line In Indonesia

-

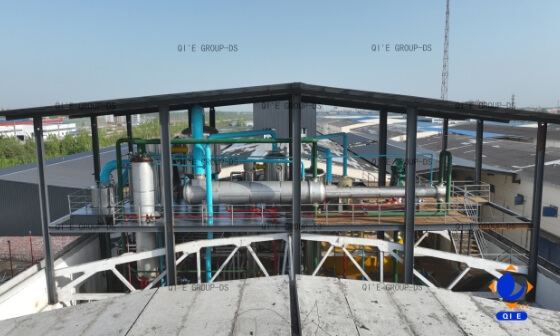

400TPD Rice Bran Oil Solvent Extraction Plant In China

-

100TPD Edible Oil Refining Project In China

-

300TPD Soybean Oil Production Line In Egypt

-

300TPD Soybean Oil Processing Line In Egypt

-

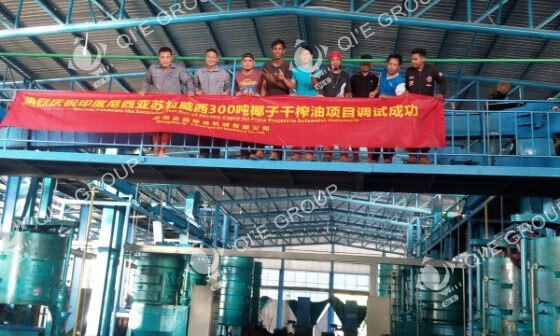

300TPD Copra Oil Production Line In Indonesia

Language

Language