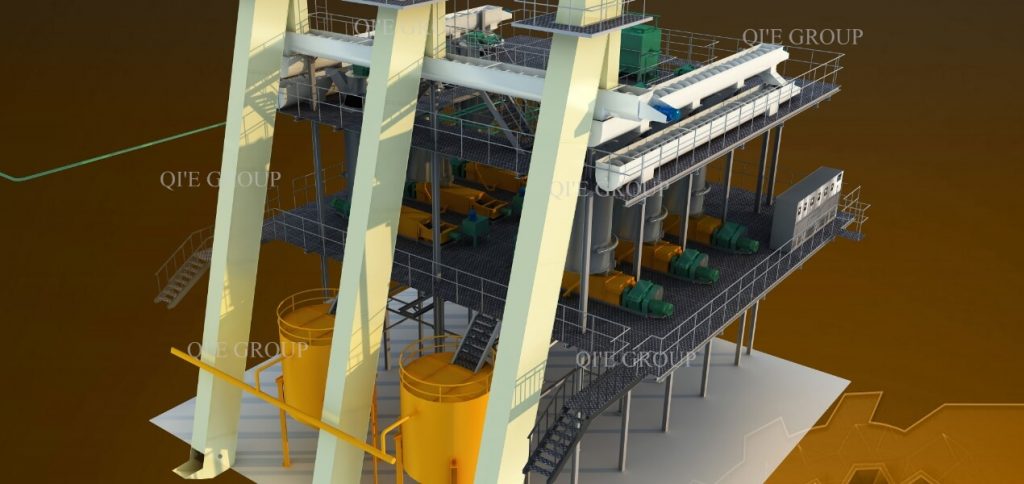

Palm Fruit/Kernel Oil Production Line

Palm Oil is extracted from fresh fruit bunches (FFB) by a mechanical process. Production capacity: 1-120TPH.

The main process of the palm oil factory includes: sterilization, threshing, pressing, clarification, purification, drying and storage.

For the kernel line, there are steps such as nut/fiber separation, nut conditioning and cracking, cracked mixture separation, and kernel drying and storage. The dried kernels are often sold to palm kernel crushers for extraction of crude palm kernel oil.

Palm Fruit/Bunch Reception:

Palm fruit bunch is transported to factory by truck.after the weighbridge weighting, driving to unloading platform, unload the fruit bunch through Ramp into hopper.

Palm Fruit Sterilization:

The palm fruit transported to sterilizer by FFB loading conveyor, sterilizing for 1 hour.The mixing be separated out is collected in catch oil pool to reclaimed oil, and the condensate be pumped to sewage treatment station.

Palm Fruit Threshing:

Strong vibrations through the palm fruit from palm fruit bunches separated.

Palm Fruit Crushing and Pressing:

Mixing tank will mash and crush palm fruit until broken after fruit threshing.The broken palm fruit flow into the palm oil press machine to pressing. Oil and water mixture outflow from pressing chamber shell hole, in the same time, the fiber cake and core was discharged from bonehead clearance and then drop in the packing anger of broken cake.

Fiber, Cake, Shell and Kernel Separation:

The extrued fiber pie enters air separation system after crushed to get separation of fibers and cores.

Crusher divided fruit core into palm kernel and shell after separated with fiber. Air separation and washing systems separate palm kernels and shells. Shells enters boiler system as fuel, and palm kernels are storage after drying.

Palm Oil Clarification:

Crude palm oil first diluted with water washing, through settlement and filtration, the fiber material removed from the oil, and then carry out continuous settlement, the whole divided into two parts: oil and sediment. The oil and the sludge will be taken out.

Palm kernel recovery section:

The pressed palm fiber cake gets into the cake breaker then get into the winnowing system to separate the fiber and nut. Then nut will be crushed to get shell and kernel. Through winnowing and washing system to separate the shell and kernel. The shell can be used as fuel for boiler, the kernel will be dried for storage.

Successful Cases

-

2000TPD Palm Fruit Oil Production Line In Indonesia

2000TPD Palm Fruit Oil Production Line In Indonesia -

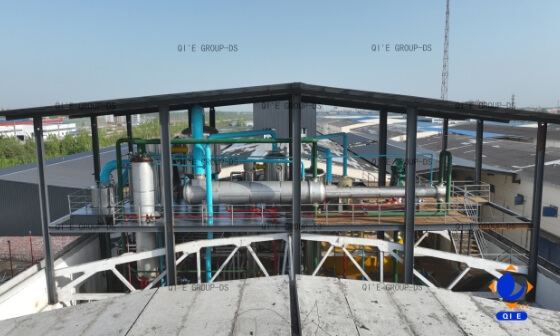

400TPD Rice Bran Oil Solvent Extraction Plant In China

400TPD Rice Bran Oil Solvent Extraction Plant In China -

100TPD Edible Oil Refining Project In China

100TPD Edible Oil Refining Project In China -

300TPD Soybean Oil Production Line In Egypt

300TPD Soybean Oil Production Line In Egypt -

300TPD Soybean Oil Processing Line In Egypt

300TPD Soybean Oil Processing Line In Egypt -

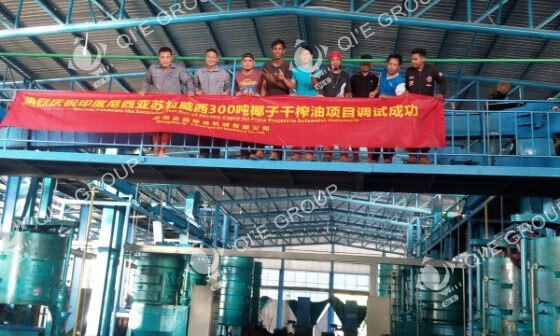

300TPD Copra Oil Production Line In Indonesia

300TPD Copra Oil Production Line In Indonesia -

200TPD Soybean Protein Isolate Project In Serbia

200TPD Soybean Protein Isolate Project In Serbia -

200TPD Soybean Oil Production Line In Russia

200TPD Soybean Oil Production Line In Russia -

200TPD Cooking Oil Production Line In Uzbekistan

200TPD Cooking Oil Production Line In Uzbekistan -

150TPD CottonSeed Oil Production Line In Uzbekistan

150TPD CottonSeed Oil Production Line In Uzbekistan -

120TPD Oil Refine Production Line In Egypt

120TPD Oil Refine Production Line In Egypt -

100TPD Palm Fruit Oil Production Line In Thailand

100TPD Palm Fruit Oil Production Line In Thailand

Language

Language