Pre-treatment and Pre-pressing Technology

Different vegetable oils have different technological requirements in the oil making process. Therefore, the oil should be treated with a series of treatments before oil extraction, so that the oil can achieve the best oil extraction quality and meet the requirements of different oil extraction processes.

Pretreatment includes Seed Cleaning & Weighing, Cracking & Dehulling, Flaking, Cooking, Pre-Pressing, Oil Residue Separation.

1. Cleaning

Using magnetic separator, weighing scale and screener to remove impurities of the seeds.

2. Cracking & Dehulling

Crushing the oilseeds to ensure good softening and flaking effect.

3.Flaking

The roller flaker has uniform crushing and flake the broken seeds into thin flakes for the oil mechanical pressing.

4. Cooking

Using heating and cooking to adjust temperature and moisture of the seeds,improving oil yield.

5. Pre-Pressing

Pressing the high-oil material to get oil and cake.then treated by solvent extraction.

The purpose of edible oil pretreatment:

1. Reduce oil loss and increase oil yield.

2. Improve the purity and quality of the by-products of the oil cake machine.

3. Reduce the wear and tear on the equipment and prolong the service life.

4. Avoid production accidents and improve the reasonable processing capacity of equipment; reduce dust and improve the workshop environment to ensure stable production.

Successful Cases

-

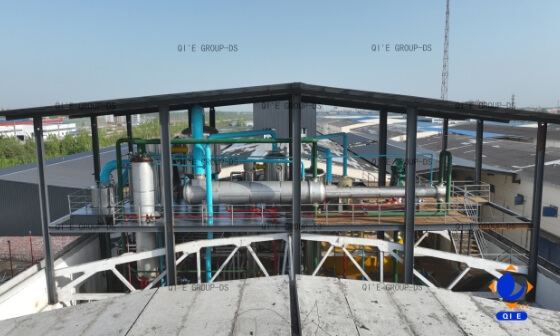

2000TPD Palm Fruit Oil Production Line In Indonesia

2000TPD Palm Fruit Oil Production Line In Indonesia -

400TPD Rice Bran Oil Solvent Extraction Plant In China

400TPD Rice Bran Oil Solvent Extraction Plant In China -

100TPD Edible Oil Refining Project In China

100TPD Edible Oil Refining Project In China -

300TPD Soybean Oil Production Line In Egypt

300TPD Soybean Oil Production Line In Egypt -

300TPD Soybean Oil Processing Line In Egypt

300TPD Soybean Oil Processing Line In Egypt -

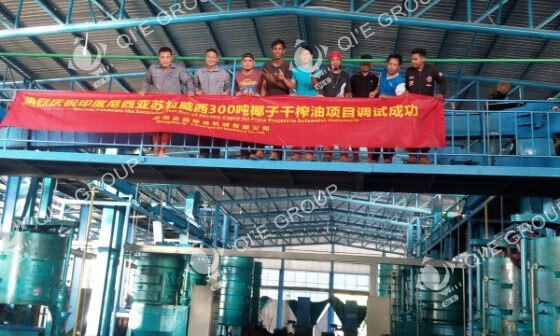

300TPD Copra Oil Production Line In Indonesia

300TPD Copra Oil Production Line In Indonesia -

200TPD Soybean Protein Isolate Project In Serbia

200TPD Soybean Protein Isolate Project In Serbia -

200TPD Soybean Oil Production Line In Russia

200TPD Soybean Oil Production Line In Russia -

200TPD Cooking Oil Production Line In Uzbekistan

200TPD Cooking Oil Production Line In Uzbekistan -

150TPD CottonSeed Oil Production Line In Uzbekistan

150TPD CottonSeed Oil Production Line In Uzbekistan -

120TPD Oil Refine Production Line In Egypt

120TPD Oil Refine Production Line In Egypt -

100TPD Palm Fruit Oil Production Line In Thailand

100TPD Palm Fruit Oil Production Line In Thailand

Language

Language