Oil Solvent Extraction Process

The solvent extract process is the basic principle of using solvent, can dissolve grease by wet permeability, molecular diffusion and convection-diffusion effect, the material came out of the germ oil extraction, and then by solvent separation of the mixed oil and fat, hair oil recovered solvents, as well as to soybean meal in solvent recovery, leaching pulp.

Direct solvent extraction system refers to the process in which the oil is pretreated and then directly enters the extractor for leaching to obtain grease. This process is suitable for low oil yield oilseeds, such as soybeans, rice bran, cottonseed and so on.

Pre-press + solvent extraction system refers to a process in which a part of the oil is squeezed out with an oil press after the oil is pretreated, and then the remaining part of the oil in the pressed cake is taken out by the leaching method. This process is suitable for high oil yield oilseeds, such as rapeseed, peanut, sunflower seed, etc.

Capacity: 100TPD-5000TPD

Oil Solvent Extraction Process

1. Solvent Extraction

Oilseed flakes are conveyed to the extractor, then extracted by miscella with different concentration gradients and fresh solvent. The miscella will be pumped to the evaporation system and the spent meal will be desolvated.

2. Evaporation System

Miscella will be pumped into the evaporation system after removing impurities twice. The evaporation system consists of 1st stage evaporator, 2nd stage evaporator and a stripping tower. The solvent evaporated from miscella will be recycled.

3. D.T.D.C

Wet meal after solvent extraction containing a certain amount of solvent will be conveyed to D.T.D.C for desolventizing, toasting, drying and cooling.

4. Solvent Recycling

The n-hexane evaporated from each section is recycled to the solvent tank through the condenser. The uncondensed gas enters the exhaust condenser and most of the uncondensed n-hexane is condensed. A small amount of n-hexane vapor and non-condensable gas enters the absorption tower in which n-hexane is absorbed by mineral oil. Other non-condensable gas is exhausted through the exhaust fan.

Successful Cases

-

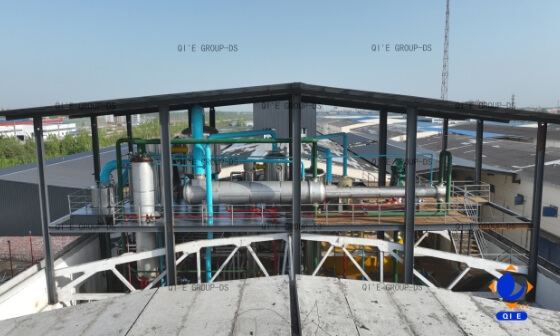

2000TPD Palm Fruit Oil Production Line In Indonesia

2000TPD Palm Fruit Oil Production Line In Indonesia -

400TPD Rice Bran Oil Solvent Extraction Plant In China

400TPD Rice Bran Oil Solvent Extraction Plant In China -

100TPD Edible Oil Refining Project In China

100TPD Edible Oil Refining Project In China -

300TPD Soybean Oil Production Line In Egypt

300TPD Soybean Oil Production Line In Egypt -

300TPD Soybean Oil Processing Line In Egypt

300TPD Soybean Oil Processing Line In Egypt -

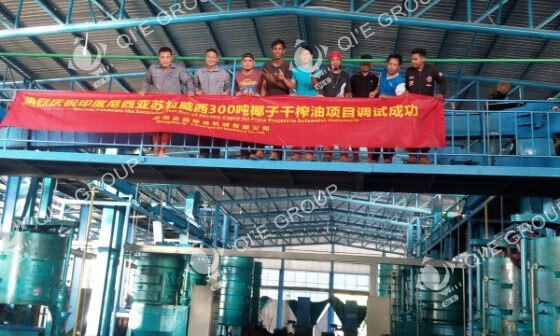

300TPD Copra Oil Production Line In Indonesia

300TPD Copra Oil Production Line In Indonesia -

200TPD Soybean Protein Isolate Project In Serbia

200TPD Soybean Protein Isolate Project In Serbia -

200TPD Soybean Oil Production Line In Russia

200TPD Soybean Oil Production Line In Russia -

200TPD Cooking Oil Production Line In Uzbekistan

200TPD Cooking Oil Production Line In Uzbekistan -

150TPD CottonSeed Oil Production Line In Uzbekistan

150TPD CottonSeed Oil Production Line In Uzbekistan -

120TPD Oil Refine Production Line In Egypt

120TPD Oil Refine Production Line In Egypt -

100TPD Palm Fruit Oil Production Line In Thailand

100TPD Palm Fruit Oil Production Line In Thailand

Language

Language