Oil Solvent Extraction Machinery

Oil extractor is the most important machine of cooking oil solvent extraction plant,and its quality is directly related to various economic and technical indicators of extraction production. Therefore, a reasonable selection of the extractor is of great significance for improving production efficiency, reducing production costs, and improving economic benefits.

Main extractors in market

01

Rotary Extractor(Capacity 100-2000 TPD)

The Rotary Extractor is the most commonly used cooking oil extractor. Its main characteristics are high material layer, high mixed oil concentration, simple structure, and convenient operation and maintenance.

02

Chain Extractor (Capacity 100-5000TPD)

The chain extractor is used for various oil extraction. Its structural feature is that the annular structure separated from the upper and lower layers is merged into a unified box-type structure. Under the action of the turning mechanism, the material can be turned completely, so the permeability is very good.

03

Loop type extractor(Capacity 100-2500 TPD)

- Low maintenance cost

- Easy to operate with low power consumption

- High oil out rate, low solvent consumption

Successful Cases

-

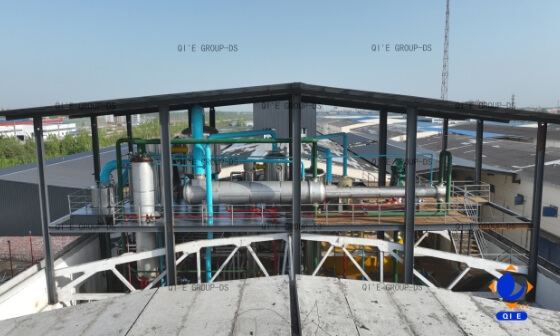

2000TPD Palm Fruit Oil Production Line In Indonesia

2000TPD Palm Fruit Oil Production Line In Indonesia -

400TPD Rice Bran Oil Solvent Extraction Plant In China

400TPD Rice Bran Oil Solvent Extraction Plant In China -

100TPD Edible Oil Refining Project In China

100TPD Edible Oil Refining Project In China -

300TPD Soybean Oil Production Line In Egypt

300TPD Soybean Oil Production Line In Egypt -

300TPD Soybean Oil Processing Line In Egypt

300TPD Soybean Oil Processing Line In Egypt -

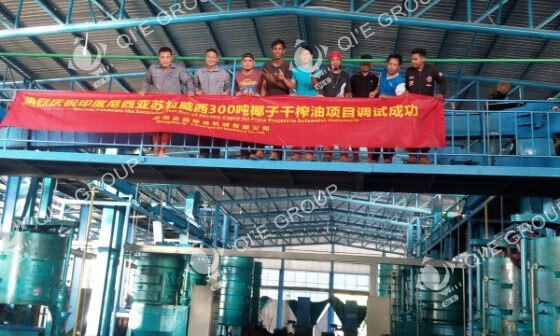

300TPD Copra Oil Production Line In Indonesia

300TPD Copra Oil Production Line In Indonesia -

200TPD Soybean Protein Isolate Project In Serbia

200TPD Soybean Protein Isolate Project In Serbia -

200TPD Soybean Oil Production Line In Russia

200TPD Soybean Oil Production Line In Russia -

200TPD Cooking Oil Production Line In Uzbekistan

200TPD Cooking Oil Production Line In Uzbekistan -

150TPD CottonSeed Oil Production Line In Uzbekistan

150TPD CottonSeed Oil Production Line In Uzbekistan -

120TPD Oil Refine Production Line In Egypt

120TPD Oil Refine Production Line In Egypt -

100TPD Palm Fruit Oil Production Line In Thailand

100TPD Palm Fruit Oil Production Line In Thailand

Language

Language