Pre-treatment Process And Press Process

We supply the whole edible oil pressing line. It contains pre-treatment process and press process. Production Capacity:10-1000TPD

Material: sunflower seed, peanut, rapeseed, copra, sesame, soybean and so on.

Main process include: Seed Cleaning & Weighing, Crushing, Flaking, Cooking, Pressing, Filtering.

1. Cleaning

Using magnetic separator, weighing scale, and screener to remove impurities of the seeds.

2. Cracking

Crushing the oilseeds to ensure a good softening and flaking effect.

3. Flaking

The roller flaker can crush and flake uniformly the broken seeds into thin flakes for the oil mechanical pressing.

4. Cooking

Using heating and cooking to adjust temperature and moisture of the seeds, improving oil yield.

5. Pressing

Pressing the high-oil material to get oil and cake, then treated by solvent extraction.

6. Filtering

Separating oil residue by oil drag conveyor firstly, crude oil then enters to settling tank for further separation. Crude oil from settling tank is pumped to a horizontal screw centrifuge or leaf filter for further removing impurities.

Successful Cases

-

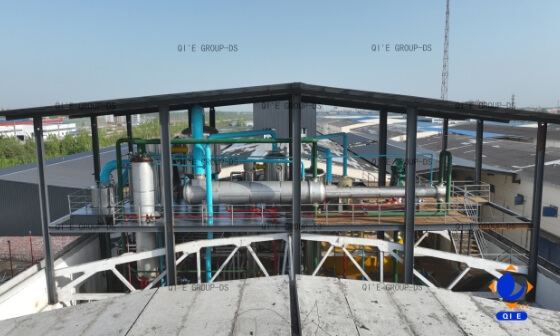

2000TPD Palm Fruit Oil Production Line In Indonesia

2000TPD Palm Fruit Oil Production Line In Indonesia -

400TPD Rice Bran Oil Solvent Extraction Plant In China

400TPD Rice Bran Oil Solvent Extraction Plant In China -

100TPD Edible Oil Refining Project In China

100TPD Edible Oil Refining Project In China -

300TPD Soybean Oil Production Line In Egypt

300TPD Soybean Oil Production Line In Egypt -

300TPD Soybean Oil Processing Line In Egypt

300TPD Soybean Oil Processing Line In Egypt -

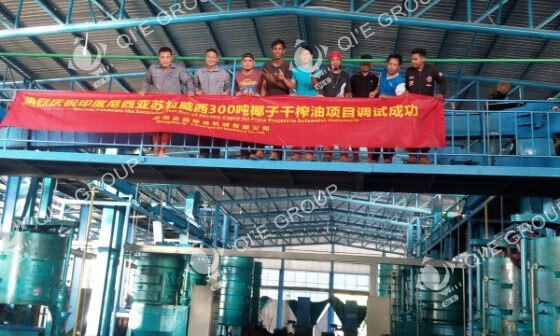

300TPD Copra Oil Production Line In Indonesia

300TPD Copra Oil Production Line In Indonesia -

200TPD Soybean Protein Isolate Project In Serbia

200TPD Soybean Protein Isolate Project In Serbia -

200TPD Soybean Oil Production Line In Russia

200TPD Soybean Oil Production Line In Russia -

200TPD Cooking Oil Production Line In Uzbekistan

200TPD Cooking Oil Production Line In Uzbekistan -

150TPD CottonSeed Oil Production Line In Uzbekistan

150TPD CottonSeed Oil Production Line In Uzbekistan -

120TPD Oil Refine Production Line In Egypt

120TPD Oil Refine Production Line In Egypt -

100TPD Palm Fruit Oil Production Line In Thailand

100TPD Palm Fruit Oil Production Line In Thailand

Language

Language