Oil Dewaxing Processing Technology

Winterization system is mainly used to separate wax from oil by low temperature crystallization.The process of cooling the fat to make the waxy crystals with a higher freezing point in the fat.

The edible oil contains a small amount of wax, which can increase the cloud point, reduce the transparency and digestion and absorption rate of the oil, and make the taste worse, thereby reducing the edible quality, nutritional value and industrial use value of the oil.

Removing or extracting wax from edible oil can achieve improve the quality of edible fats and comprehensively utilizing vegetable fat wax sources.

Sunflower seed oil, cottonseed oil rice bran oil,rapeseed oil and grape seed oil which contain high wax often need winterization and dewaxing equipment.

Winterization system is mainly used to separate wax from oil by low temperature crystallization. The process of cooling the fat to make the waxy crystals with a higher freezing point in the fat.

Dewaxing methods: conventional method, solvent method, surfactant method, combined degumming, deacidification method, etc.

Successful Cases

-

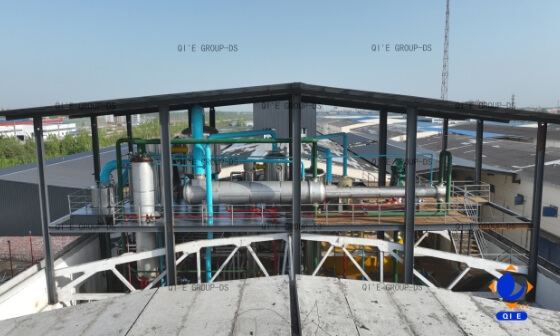

2000TPD Palm Fruit Oil Production Line In Indonesia

2000TPD Palm Fruit Oil Production Line In Indonesia -

400TPD Rice Bran Oil Solvent Extraction Plant In China

400TPD Rice Bran Oil Solvent Extraction Plant In China -

100TPD Edible Oil Refining Project In China

100TPD Edible Oil Refining Project In China -

300TPD Soybean Oil Production Line In Egypt

300TPD Soybean Oil Production Line In Egypt -

300TPD Soybean Oil Processing Line In Egypt

300TPD Soybean Oil Processing Line In Egypt -

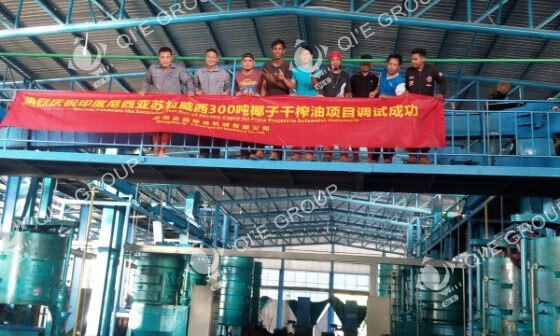

300TPD Copra Oil Production Line In Indonesia

300TPD Copra Oil Production Line In Indonesia -

200TPD Soybean Protein Isolate Project In Serbia

200TPD Soybean Protein Isolate Project In Serbia -

200TPD Soybean Oil Production Line In Russia

200TPD Soybean Oil Production Line In Russia -

200TPD Cooking Oil Production Line In Uzbekistan

200TPD Cooking Oil Production Line In Uzbekistan -

150TPD CottonSeed Oil Production Line In Uzbekistan

150TPD CottonSeed Oil Production Line In Uzbekistan -

120TPD Oil Refine Production Line In Egypt

120TPD Oil Refine Production Line In Egypt -

100TPD Palm Fruit Oil Production Line In Thailand

100TPD Palm Fruit Oil Production Line In Thailand

Language

Language