Copra Oil Production line

Copra oil production line, our company adopts physical pressing. The dried copra is crushed, softened/conditioned, twice pressed and filtered; After that, the crude oil is obtained; then the Crude copra oil can be further refined if need produce higher quality oil.

Copra oil production process

Pretreatment and twice pressing section is very important process for copra oil production. It will directly influence oil yield and oil quality.

(1) Crushing: making copra/dry coconut to suitable small pieces.

(2) Softening: The purpose of softening is to adjust the moisture and temperature of copra, and make it in best condition before into pressing process.

(3) Pre-Pressing: press the most of oil out with prepresser, the residue oil in prepressed cake of 16%-18% . Then the cake will go to twice presser process.

(4) Twice pressing: press the residue oil out.

Press

Through two squeezes, Press the cake till the oil residue is about 5%.

Refinery

According to customer needs, we can supply continuous refining and semi-continuous refining equipment include degumming, deacidification, decolorization, bleaching and deodorization, in order to remove the FFA and improve the quality of oil, extending the time of storage.

Successful Cases

-

2000TPD Palm Fruit Oil Production Line In Indonesia

2000TPD Palm Fruit Oil Production Line In Indonesia -

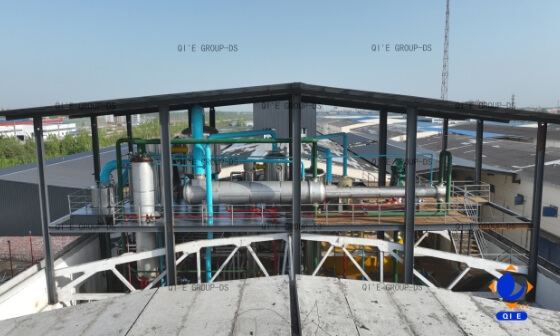

400TPD Rice Bran Oil Solvent Extraction Plant In China

400TPD Rice Bran Oil Solvent Extraction Plant In China -

100TPD Edible Oil Refining Project In China

100TPD Edible Oil Refining Project In China -

300TPD Soybean Oil Production Line In Egypt

300TPD Soybean Oil Production Line In Egypt -

300TPD Soybean Oil Processing Line In Egypt

300TPD Soybean Oil Processing Line In Egypt -

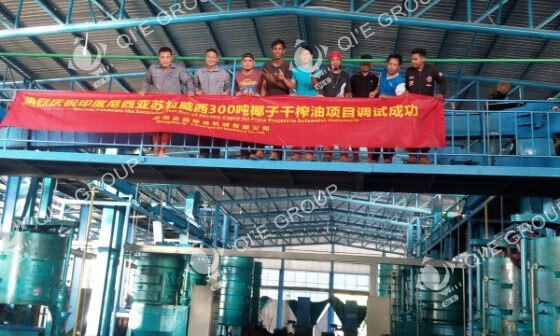

300TPD Copra Oil Production Line In Indonesia

300TPD Copra Oil Production Line In Indonesia -

200TPD Soybean Protein Isolate Project In Serbia

200TPD Soybean Protein Isolate Project In Serbia -

200TPD Soybean Oil Production Line In Russia

200TPD Soybean Oil Production Line In Russia -

200TPD Cooking Oil Production Line In Uzbekistan

200TPD Cooking Oil Production Line In Uzbekistan -

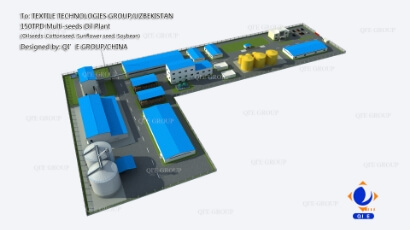

150TPD CottonSeed Oil Production Line In Uzbekistan

150TPD CottonSeed Oil Production Line In Uzbekistan -

120TPD Oil Refine Production Line In Egypt

120TPD Oil Refine Production Line In Egypt -

100TPD Palm Fruit Oil Production Line In Thailand

100TPD Palm Fruit Oil Production Line In Thailand

Language

Language